Tundish Nozzles

Tundish Nozzles

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting.

- Long casting sequence time

- Controlled casting speed

- Excellent resistance to oxidation

- Prevent clogging to improve productivity

- Special compositions of nozzles as per use in the industry

These are highly suitable for open casting. We offer two types of Tundish Nozzles as mentioned below:

- Alumina-carbon Tundish Nozzle and Zirconia Insert

- Fully Zirconia Nozzles of different designs

Our Zirconia Nozzles are very dense having AP < 5%, Bulk Density > 5.4g/cc and allows a steady flow of metal stream to the mould. Capable of withstanding a casting duration of 12 hours.

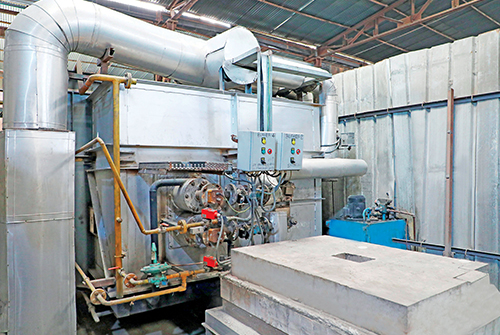

1700 0C Furnace

| TYPICAL PROPERTIES OF PURGING & SHAPED REFRACTORY PRODUCTS | |||||||||

| Product | Zirconia Insert Tundish Nozzle | ||||||||

| Chemical Analysis (%) | |||||||||

| ZrO2 (Min.) % | 95 | ||||||||

| Al2 O3 (Min.) % | NA | ||||||||

| Fe2 O3 (Max.) % | 0.2 | ||||||||

| MgO (Max.) % | NA | ||||||||

| SiO2 (Max.) % | 2 | ||||||||

| CaO (Max.) % | NA | ||||||||

| Physical Properties | |||||||||

| A.P. (Max.) % | 5 | ||||||||

| B.D. (gm/cc) Min. | 5.2 | ||||||||

| C.C.S. (Kg./cm2) Min. | NA | ||||||||